If you’re considering replacing the roof on your home, you don’t want to skimp on the underlayment. This important material component of your roof provides a second layer of protection against the weather, guarding your home from the possibility of moisture seeping through to the roof deck. The best roof underlayment can ensure the longevity and integrity of your home’s roof.

A roof underlayment is situated between the roof deck and shingles and helps prevent water from getting into your home due to wind-driven or torrential rain. It creates an additional barrier of protection so the roof deck does not become damaged. A roof underlayment will also help reduce the risk of condensation buildup that could lead to rot and mold.

With a variety of roof underlayment types and materials to choose from, we’ll take you through the basics of roof underlayment so you know which one is best for your home. When you have the right underlayment installed on your roof, it can safeguard your home’s structure and keep the interior from becoming damaged by excess water or moisture.

A top choice for roof underlayment is DuPont Tyvek Protec 120 Roof Underlayment since it can be used for a number of different roofs, including asphalt and metal. It’s a strong and durable choice but lightweight enough to attach to the roof deck easily. DuPont Tyvek Protec can also be used as temporary roofing while you’re waiting for your new roof to be installed.

In this article:

- Types of Roof Underlayment

- Life Expectancy of Roof Underlayment

- How to Install a Roof Underlayment

- Best Roof Underlayment

- Frequently Asked Questions

Types of Roof Underlayment

| Type of Roof Underlayment | Features | Pros | Cons |

|---|---|---|---|

| Asphalt-Saturated Felt | Traditional underlayment made from organic or fiberglass material saturated with asphalt. Available in 15- or 30-pound options. |

|

|

| Rubberized Asphalt | Made by combining liquid asphalt and synthetic rubber polymers, offering superior waterproof properties. |

|

|

| Synthetic | Made from materials like polyethylene, polypropylene, polyester, or fiberglass. Offers durability, tear resistance, and waterproofing. |

|

|

| Self-Adhering | Also known as peel-and-stick underlayment. Sticks to the roof deck without needing nails or fasteners. |

|

|

| Waterproof | Provides total waterproofing, made from rubberized asphalt or synthetic materials. Protects against wind-driven rain and ice dams. |

|

|

| Foam | Synthetic underlayment that provides insulation and waterproofing. Often self-adhering and includes Spray Polyurethane Foam (SPF) for thermal resistance. |

|

|

Roof underlayment is a roofing material made from felt, synthetics, or rubberized asphalt that’s installed on top of the roof deck. This flat layer of material acts as a barrier against the elements to further protect your home from water damage. Your new roofing system is then installed on top of the roof underlayment.

There are pros and cons to different types of roof underlayment, and not all are compatible with all types of roofing. The six main types of roof underlayment include:

Asphalt-Saturated Felt Roof Underlayment

Most commonly used, asphalt-saturated felt is a traditional roofing underlayment that is also known as felt paper or tar paper. This type of roofing underlayment provides basic protection and has been used on roofs for decades. Asphalt-saturated felt is made using organic or fiberglass material saturated with asphalt, which makes it water-resistant.

Asphalt-saturated felt comes as either 15- or 30-pound felt, which indicates the weight of felt per 100 square feet of roofing underlayment. For instance, 15-pound felt is thinner, and therefore lighter, than 30-pound felt. Though the 15-pound felt is easier to handle and install, it’s not as durable or resistant to damage.

Pros include:

- Easy to install

- Budget-friendly

- Light and pliable

Cons include:

- Not waterproof

- May absorb moisture

- Could tear or wrinkle

Rubberized Asphalt Roof Underlayment

Rubberized asphalt is a roof underlayment that’s made by combining liquid asphalt and synthetic rubber polymers, which together create superior waterproof properties. This type of underlayment is popular in areas that are susceptible to severe weather.

Rubberized asphalt roof underlayment is more durable and of higher quality than asphalt-saturated felt underlayment. It can withstand exposure to the elements for longer periods of time.

Pros:

- Resistant to tearing

- Waterproof

- Easy to install

Cons:

- Expensive

- Not suitable for all types of roofing

Synthetic Roof Underlayment

Synthetic roof underlayment is made from materials such as polyethylene, polypropylene, polyester, or fiberglass. This type of roofing substrate lasts longer than traditional felt and offers durability, resistance to tearing, and waterproofing.

It can also handle exposure to weather for extended periods of time, including UV exposure. Synthetic underlayment is generally the preferred option for tile roofs as well.

Pros:

- Lightweight

- Easy to install and handle

- Resistant to moisture

Cons:

- Slippery

- Expensive

- Not suitable for all types of roofing

Self-Adhering Roof Underlayment

Self-adhering roof underlayment is also referred to as peel-and-stick underlayment. It’s the easiest type of underlayment to install since it sticks to the roof deck and doesn’t require nails or other fasteners to secure it to the deck. Self-adhering underlayment can be made from rubberized asphalt or synthetic materials and offers strong waterproofing capabilities.

Pros:

- Easy to install

- Creates strong bond

- Wind resistant

Cons:

- Expensive

- May not be suitable for all roofs

Waterproof Roof Underlayment

Not all roof underlayment options are fully waterproof. Though all types of underlayment have some form of resistance to water and moisture, only rubberized asphalt and synthetic materials provide total waterproofing.

Waterproof roof underlayment is designed to give you an additional layer of protection against moisture and water penetration. It’s good for protecting against wind-driven rain and ice dams.

Pros:

- Strong roof protection

- Durable and long-lasting

Cons:

- Expensive

- May not be suitable for all roofs

Foam Roof Underlayment

Foam roof underlayment is a type of synthetic roofing material that provides insulation and waterproofing benefits. Foam underlayment is often self-adhering. This type of roofing underlayment provides strong resistance to wind and guards the roof from wind-driven rain as well.

Foam roof underlayment can also be an SPF, or Spray Polyurethane Foam, which is a foam underlayment that is applied directly to the roof deck using specialized spray foam rigs. This type of underlayment offers thermal resistance and is suitable for most climates.

Pros:

- Waterproof

- Easy to install

- Wind-resistant

Cons:

- Requires regular inspections

- May break down easily

Life Expectancy of Roof Underlayment

The life expectancy of a roof underlayment can range anywhere from 20 to 35 years, depending on the material and application you choose, as well as the weather your roof is regularly exposed to. The amount of UV exposure the underlayment experiences can also affect the longevity and durability of the roofing material.

Asphalt-saturated felt can last up to 20 to 30 years, but if your roof experiences extreme weather, the underlayment may only last half as long or even less. Rubberized asphalt and synthetic materials are far more durable and can feature a lifespan of up to 35 years.

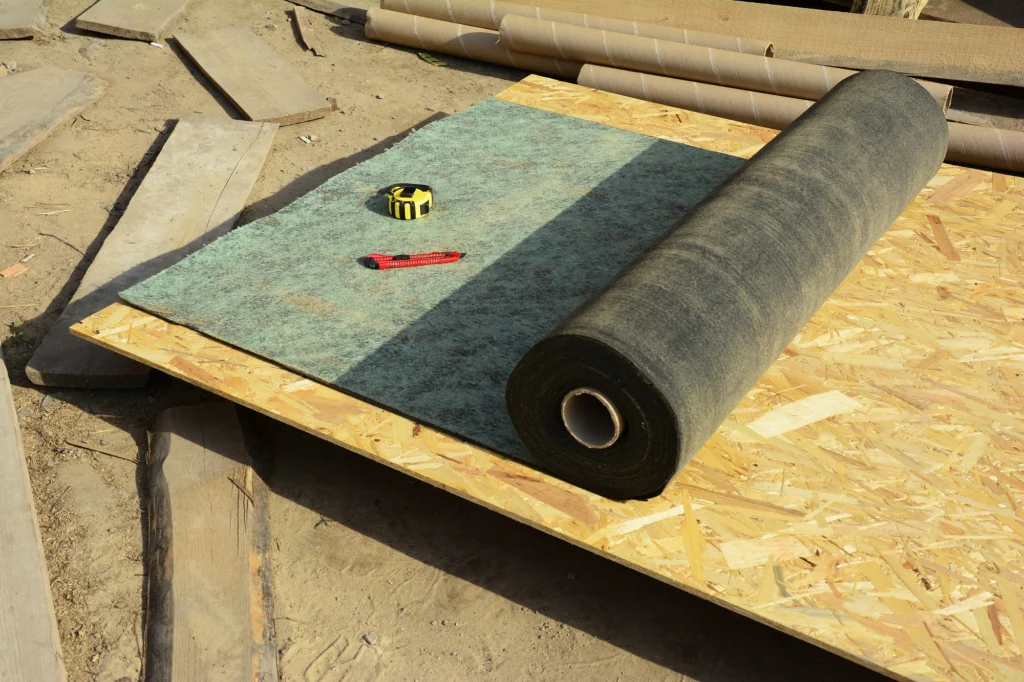

How to Install a Roof Underlayment

Roof underlayment is installed between the roof deck and the final roofing material, whether that’s asphalt shingles or metal cladding. It acts as a protective barrier to keep water and excess moisture from penetrating through the roof deck and seeping inside to the attic or upper levels of your home.

To install roof underlayment, consider the following:

- Strip the old roof: Remove the old roofing first. You’ll need to strip away all of the old roofing, including the old underlayment, in order to expose your roof deck.

- Clean and repair the roof deck: Clean the roof deck and make any necessary repairs to ensure your new roof underlayment can be applied properly to the roof deck.

- Install the new roof underlayment: Read the instructions that came with your underlayment and follow the steps given. Be sure to adhere or fasten the underlayment securely, overlapping pieces to help prevent leaks and damage. Work to eliminate creases and bubbles so your underlayment is laid flat against the roof deck.

- Replace drip edge flashing: Install drip edge flashing and fasten it to the sheathing. Consider using a waterproof underlayment around the part of your roof that overhangs the eaves to help prevent ice dams.

- Install new roofing on top of underlayment: Install your new roofing material on top of the underlayment.

The Best Roof Underlayment

Best Overall Roof Underlayment – DuPont Tyvek Protec 120 Roof Underlayment

DuPont Tyvek Protec 120 Roof Underlayment is the best overall roof underlayment since it’s designed for strength, durability, and compatibility. This roof underlayment is structured from synthetic materials and can be used with asphalt shingles, cedar shingles, and metal roofs. Its compatibility with different types of roofing materials makes it a good choice for roof repairs or new roof replacement.

Tyvek Protec roof underlayment features a high strength-to-weight ratio, but the material is lightweight and easy to work with. This roof underlayment features an embossed pattern with a slip-resistant coating and grooves that help expel water, so there’s better traction and grip for walking on it, all of which means it’s suitable for steep slopes.

Tyvek Protect roof underlayment provides moisture protection while guarding against UV exposure for up to 3 months, making it a good temporary barrier before you need to install a new roof on top of it. The wrinkle-free surface also makes for smoother roof installations.

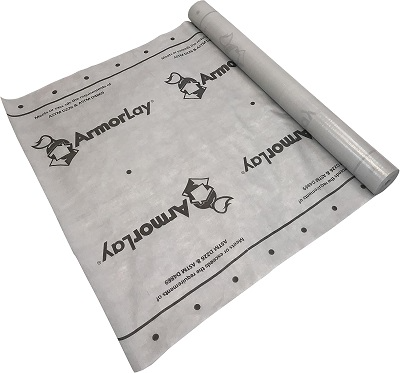

Best Synthetic Roof Underlayment – ArmorLay 25 Synthetic Roof Underlayment

ArmorLay 25 Synthetic Roof Underlayment is the best synthetic roof underlayment because it’s 5 times stronger and lighter — weighing less than 25 pounds — than traditional asphalt felt underlayment and provides 5 times more coverage with one roll. This roof underlayment also meets the necessary performance standards for roofing.

The ArmorLay synthetic underlayment is waterproof and guards against UV exposure for up to 60 days, allowing you to use it as temporary protection for new construction. This roof underlayment is slip-resistant and suitable for a variety of roofing applications, including installation on steep roofs.

Best Roof Underlayment for Asphalt Shingle Roofs – Grace Select Roofing Underlayment

The best roof underlayment for asphalt shingle roofs is Grace Select Roofing Underlayment. This type of underlayment is a rubberized asphalt that is self-adhering. Crafted to provide a high-level ratio of strength to weight, Grace Select features a slip-resistant film and is suitable for applying on steep slopes with asphalt shingles.

Grace Select is lightweight, easy to apply, and has a surface that allows for better traction. The peel-and-stick method of this underlayment gives your roof protection against wind-driven rain and ice dams while providing an additional barrier against possible leaks from damaged roofing shingles.

Grace Select gives you a wrinkle-free surface for smoother installations while remaining pleasing to the eye, so it looks good during new construction or before you can get your new roof put on. Plus, it can withstand up to 30 days of UV exposure.

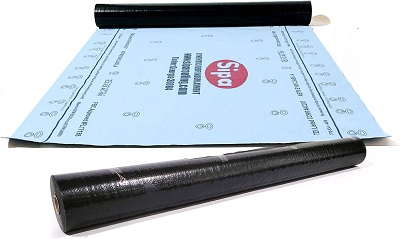

Best Roof Underlayment for Metal Roofs – SIPA 100 GSM Synthetic Waterproof Roof Underlayment

For metal roofs, the best roof underlayment is the SIPA 100 GSM Synthetic Waterproof Roof Underlayment. This synthetic roofing underlayment is designed to enhance the life of your roof with its superior resistance to water and UV rays — for up to 60 days. The SIPA roof underlayment is ideal for sloped roofs, including both asphalt and metal.

The smooth underlayment material has both a waterproof and anti-aging layer, which creates a durable, long-lasting application that protects your roof deck against water leaks. Whether you’re doing repairs or a total roof replacement, the SIPA roof underlayment is lightweight, easy to work with, and compatible with most roofs.

Best Peel and Stick Roof Underlayment – MFM Peel & Seal Roll Roofing

MFM Peel & Seal Roll Roofing is the original, patented, peel-and-stick roof underlayment. Ideal for most roofs, especially those that may be difficult to waterproof, this peel-and-stick roof underlayment is made from an aluminum composite foil and polymer films. Featuring a rubberized asphalt backing, it’s flexible, tear-resistant, and won’t dry or crack.

The MFM Peel & Seal roof underlayment can be used for all types of surfaces, including asphalt and metal roofs. Different from most types of roof underlayment, this option is designed to reflect heat and water without additional coverage; its durability allows it to be left exposed indefinitely. It’s easy to apply to low and steep slopes, making it a great option for most roofing applications.

Frequently Asked Questions

What is the new type of roof underlayment?

The new type of roof underlayment is made from synthetic materials. Synthetic underlayment is more durable and lasts longer than traditional asphalt-saturated felt.

Can you put new underlayment over old roof underlayment?

It’s not recommended to put new underlayment over older underlayment because it could lead to several issues and increase the risk of damage. The new roof underlayment may not adhere or fasten to the old underlayment well, which could increase the risk for gaps that may promote water penetration.

How often should roof underlayment be replaced?

How often roof underlayment needs replacing depends on what type of roofing material was installed and the weather conditions your roof experiences. Asphalt-saturated felt can last up to 30 years, while rubberized asphalt and synthetic materials can last up to 35 years. But consider replacing the underlayment sooner if you spot problems or your roof recently sustained damage.

Will a roof leak with just underlayment?

Not all roof underlayment is waterproof. Some materials, such as asphalt-saturated felt, are only considered water-resistant. If left exposed to the elements long enough without a proper roof top, water leaks could happen.

What is the most common material used for roof underlayment?

Asphalt-saturated felt is the most common material used for roof underlayment. It comes in two thicknesses: 15 and 30 pounds.

What is the best roof underlayment for tile roofs?

Synthetic underlayment is generally considered the best option for tile roofs due to its superior durability, water resistance, and ability to withstand high temperatures. It offers better protection against moisture and UV exposure compared to traditional felt underlayment, making it ideal for supporting the weight of tiles while providing long-lasting performance